Knowledge Center

Rheological characterization of polymeric solutions used in spray drying process

Abstract

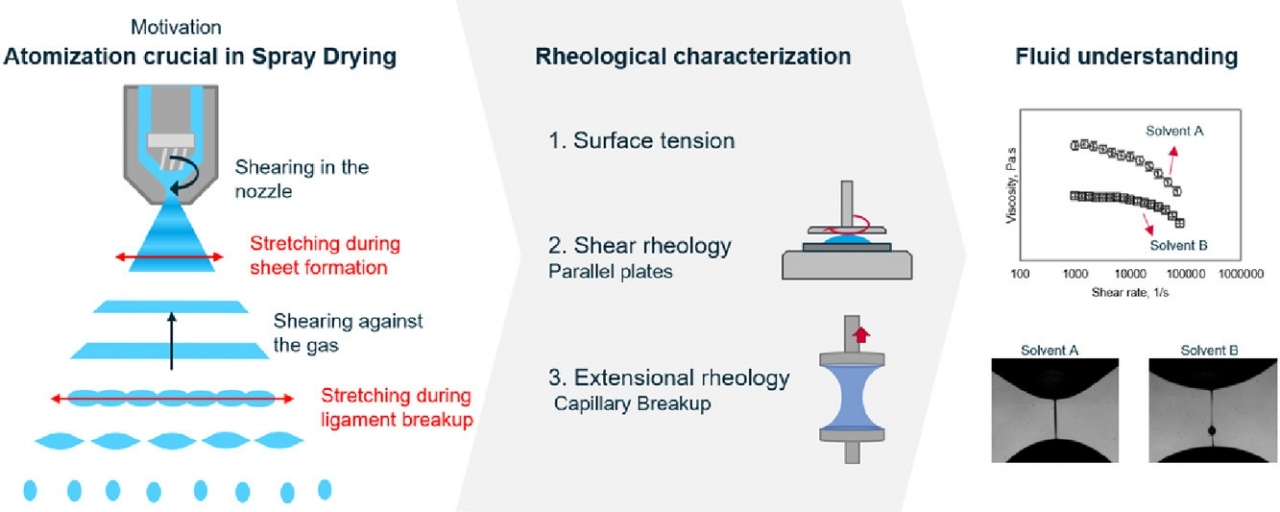

The present works contributes with a rheological characterization of the most commonly used polymers and solvents to formulate amorphous solid dispersions by means of spray drying process: copovidone, hydroxypropyl methylcellulose (HPMC), hydroxypropyl methylcellulose acetate succinate (HPMCAS) and a copolymer of methacrylic acid and methyl methacrylate (1:1 ratio and commercially known as Eudragit L100). The organic-based solutions are characterized in terms of surface tension, shear viscosity and relaxation time. HPMC and HPMCAS solutions exhibit shear thinning behaviour, i.e. decrease of shear viscosity with the increasing shear rate imposed, while the samples with Eudragit L100 can be considered Boger fluids, showing a constant viscosity but maintaining its viscoelastic character. Under uniaxial extensional flow, these polymers solutions exhibit a viscoelastic behavior with an increasing relaxation time with an increasing concentration, and in some cases showed a ‘beads-on-string’ effect. In contrast, copovidone showed a Newtonian fluid behavior, with the absence of elasticity. The fundamental understanding and characterization of the present work may be further applied to atomization modelling and support and expedite spray drying process development.

Read article here